Our quality system is based on the ISO 9001:2015 & ISO TS16949 standard. Integral to that standard is our commitment to continuous improvement in all aspects of our business. Cross-functional teams are used in advanced product planning from process design through validation and PPAP. To further insure that your product meets specification, we utilize tools such as SPC, precision optical gauging equipment and a comprehensive predictive and preventative maintenance program.

The most common inspection equipment used today is the CMM or DIGITAL HEIGHT GAUGE. Our machines are annually calibrated and are accurate to 5 microns (0.005mm). They are automated and programmable to check as many points or parts needed. They can be programmed to CAD or to print, roadmaps are created to insure efficiency in comparison of variable data.

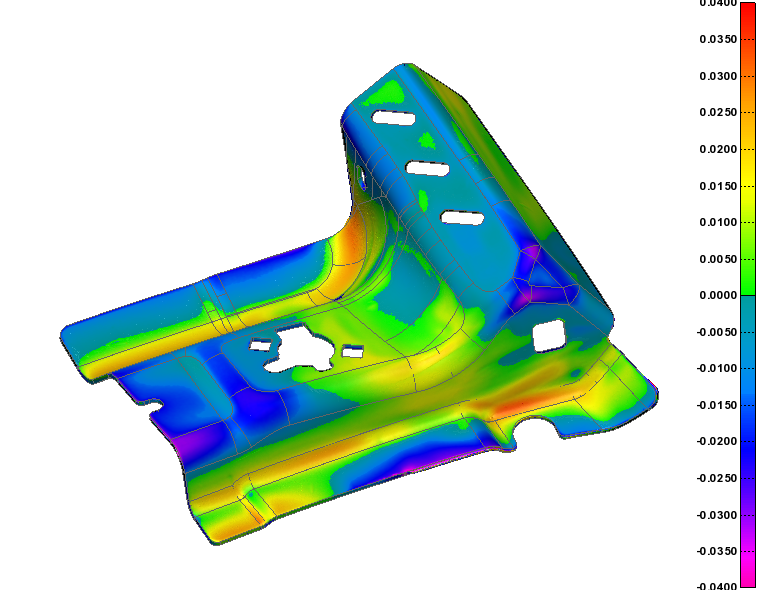

SERVICE SYNDICATE utilizes the most current technology to rapidly move prototypes into production. The HYBRID laser Blue Light Scanner can provide a full color representation “Heat Map” that is accurate within 20 microns (0.02mm) and repeatable to 40 microns. It’s ability to rapidly check components, assemblies and fixtures makes the Blue Light Scanner the tool of choice. Utilizing the GEOMAGIC Software enables us to provide a wide range of report options that includes all required variable data, heat map, trend charts, capability and can export data into excel or word formats so we can provide the information on your form or spreadsheet.

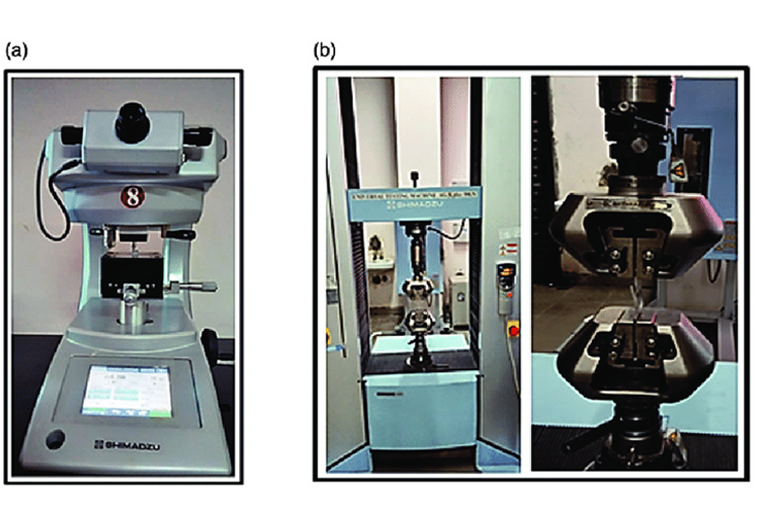

SERVICE SYNDICATE offers in house metallurgy services. Our NABL accredited laboratory is where we certify all of our welds using microscopic cut and etch technology. Simply put, a weld is cut across the joint and then polished. Nitric Acid is added to the surface, which makes the weld and parent metal appear dissimilar to each other. This sample can then be placed under a microscope and the various parts of the weld can be measured to customer specifications.

Our met lab also has an electromagnetic tension and compression tester. We perform in house pull tests and can test yield and tensile on different types of materials. This piece of equipment and technology is a must and is required in order to accurately hot stamp parts and verify that the tensile and yield are within spec on the finished product.