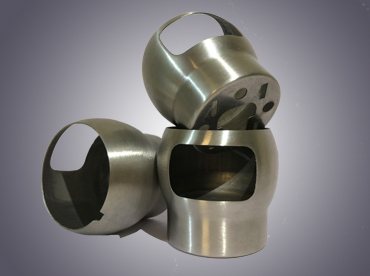

This precision formed and bulged cylindrical part, which is used in various door lock applications. This part is rigorously tested on well-defined parameters under strict vigilance of our experienced and qualified engineers and lifecycle test performed by third party.

Produced from stainless steel 304 and abrasive buffing finish, it is formed on a 300 TON SEW in die transfer press. All of the tooling was designed and fabricated at SERVICE SYNDICATE. The bulging operation performed in specially design hydraulic press tool.

The estimated annual usage of this product is 2,400,000 units.

| HIGHLIGHTS OF STAMPINGS OF CYLINDRICAL KNOB | ||

|---|---|---|

| Product Description | Primary | Secondary |

Stamping Capabilities Applied/Processes |

Die Design and Manufacturing In-Die transfer tool design |

Inspection Cosmetic inspection packaging |

Equipment Used to Manufacture Part |

SEW 300 TON power press | |

Tightest Tolerances |

± 0.05 mm | |

Material Used |

Mild Steel | |

In process testing/inspection performed |

Dimensional Inspection

|

|

Industry for Use |

Lock and Security | |

Volume |

2,400,000 Units Annually | |

Delivery/Turnaround Time |

3 - 4 Weeks After Receipt of Order | |

Standards Met |

Customer Supplied Print, 2D CAD Drawing | |

Product Name |

Cylindrical Knob | |