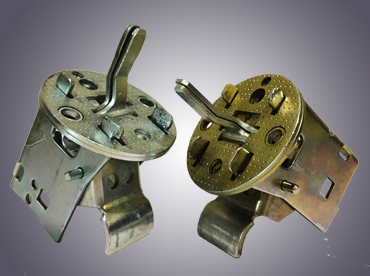

This precision formed and assembled finger lever is part of an internal cylindrical lock knob. It is designed as an in-lock dead bolt opening device for personal access to desired area of office or home.

Produced from cold rolled mild steel and zinc plated, it is formed on SEW 60 TON press. All of the tooling was designed and fabricated here at SERVICE SYNDICATE engineering including all of the shaped die work. The assembly performed along with five types of different gauges to meet the customer specific performance standards. SERVICE SYNDICATE clearly achieved and mastered the art of assembling these lock components with rejection rate of zero PPM.

The estimated annual usage of this product is 2,400,000 units.

| HIGHLIGHTS OF FINGER LEVER ASSEMBLY | ||

|---|---|---|

| Product Description | Primary | Secondary |

Stamping Capabilities Applied/Processes |

Die Design and Manufacturing progressive feed tool design |

Inspection Zinc plating Functional testing packaging |

Equipment Used to Manufacture Part |

SEW 60 TON power press | |

Tightest Tolerances |

± 0.050 mm | |

Material Used |

Mild Steel | |

In process testing/inspection performed |

Dimensional Inspection

|

|

Industry for Use |

Lock and Security | |

Volume |

2,400,000 Units Annually | |

Delivery/Turnaround Time |

3 - 4 Weeks After Receipt of Order | |

Standards Met |

Customer Supplied Print, 2D CAD Drawing | |

Product Name |

Finer Lever Assembly | |