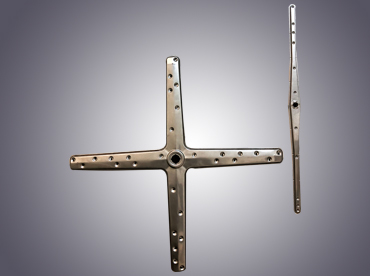

The main function of dishwater spray arms is to shoot hot and cold water at high pressures. Rotary function takes place with natural water pressure which serves as the substitute for manual scrubbing in washing dishes.

Water jet blowhole angles as well crimping of edges and surface profile are critical to quality to maintain precision while forming operation for optimal performance of the entire product.

Using a 300 TON SEW press with high frequency spot welding liner power supply designed to cut down on costing and maintain the best possible surface finish. SERVICE SYNDICATE manufactures the wash and rinse arm from grade 304 stainless steel and give buffing finish prior to shipment.

Since its inception SERVICE SYNDICATE produced approximately 96,000 units with a 3 - 4 week turnaround time.

| HIGHLIGHTS OF WASH & RINSE ARM ASSEMBLY | ||

|---|---|---|

| Product Description | Primary | Secondary |

Stamping Capabilities Applied/Processes |

Die Design and Manufacturing In-Line crimping tool design Pneumatic Spot welding SPM |

Inspection Cosmetic inspection Water Pressure test packaging |

Equipment Used to Manufacture Part |

SEW 300 TON power press with welding SPM | |

Tightest Tolerances |

± 0.100 mm | |

Material Used |

Stainless steel 304 | |

In process testing/inspection performed |

Dimensional Inspection

|

|

Industry for Use |

Commercial Heavy Appliances | |

Volume |

12,000 Units Annually | |

Delivery/Turnaround Time |

3 - 4 Weeks After Receipt of Order | |

Standards Met |

Customer Supplied Print, 3D CAD Drawing | |

Product Name |

Wash Arm Rinse Arm Assembly | |