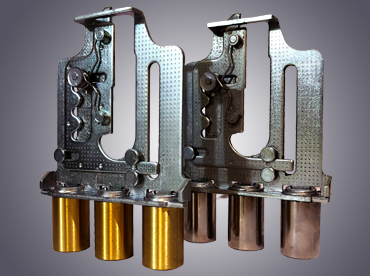

As a critical supplier and turnkey solution provider lock and security industry, SERVICE SYNDICATE produces a myriad of different assembly components with custom design process equipment and tooling to OEM customers. This slider assembly engages and disengages the locking mechanism.

Using a 110 SEW press with hydro pneumatic SPM designed to locate and press rivets along with servo indexing mechanism, SERVICE SYNDICATE manufactures the Housing from CR and CROME alloy steel and passivates it prior to shipment. SERVICE SYNDICATE Engineering produces approximately 360,000 units annually with a 3 - 4 week turnaround time.

| HIGHLIGHTS OF SLIDER DEAD BOLT ASSEMBLY | ||

|---|---|---|

| Product Description | Primary | Secondary |

Stamping Capabilities Applied/Processes |

Die Design and Manufacturing Crimping tool design Hydro pneumatic SPM Servo indexing mechanism |

Inspection Zinc and nickel plating Slide Gauge Packaging |

Equipment Used to Manufacture Part |

SEW 150 TON power press with SPM with Servo indexing die set | |

Tightest Tolerances |

± 0.050 mm | |

Material Used |

Cold rolled mild steel CROM Alloy steel |

|

In process testing/inspection performed |

Dimensional Inspection

|

|

Industry for Use |

Lock & Security | |

Volume |

360,000 units annually | |

Delivery/Turnaround Time |

3 - 4 Weeks After Receipt of Order | |

Standards Met |

Customer Supplied Print, 2D CAD Drawing | |

Product Name |

Slider Dead bolt assembly | |